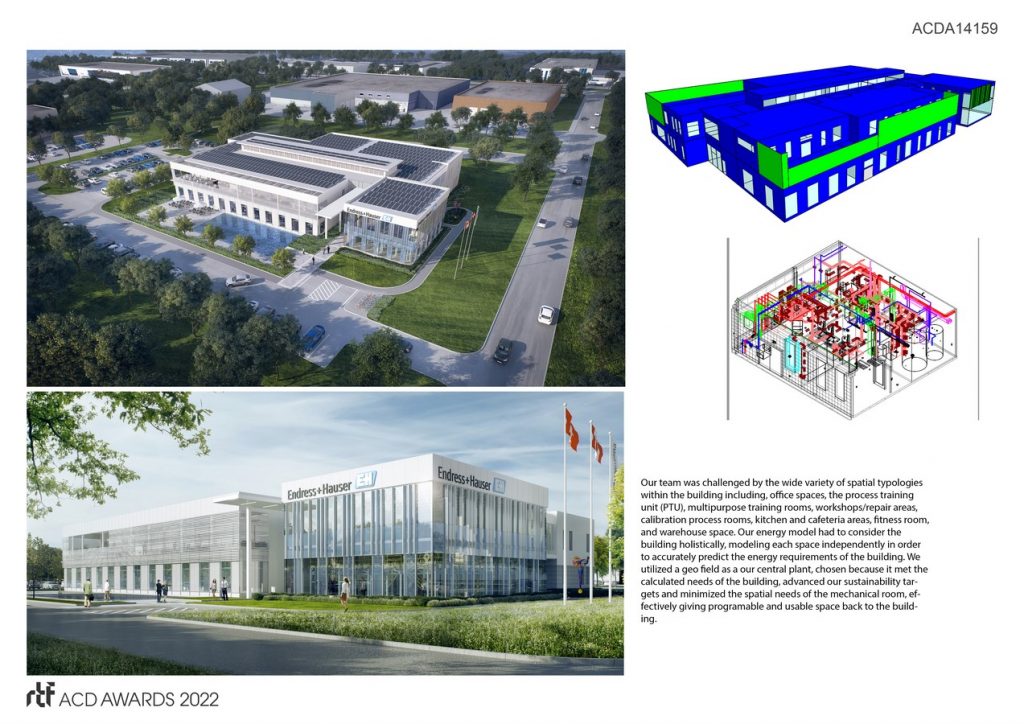

The 47,000 sq. ft. Customer Experience Centre for Endress+Hauser, a Swiss Owned corporation, established a new sustainability standard for its international portfolio of buildings. The project built within an industrial park in Burlington, Ontario, is the first privately owned project in Canada to pursue both ZCB Certification and LEED Gold simultaneously. It recently achieved ZCB Certification, the first of two sustainability milestones.

Architecture, Construction & Design Awards 2022

Second Award | Housing (upto 5 floors) (Concept)

| Project Details | |

| Project Name: | Endress+Hauser Customer Experience Centre |

| Project Category: | Industrial |

| Studio Name: | mcCallumSather |

| Design Team: | Drew Hauser, Principal in Charge; Ashraf Azeem, Design Lead; Michelle Austin, Construction Administration |

| Area: | 47,000 sq. ft. |

| Year: | 2022 |

| Location: | Burlington, ON |

| Consultants: | Mechanical Engineering: mcCallumSather |

| Structural Engineering: WSP | |

| Electrical Engineering: WSP | |

| Energy Consultants: RWDI | |

| Civil: MTE Consultants Inc. | |

| Landscape: GSP | |

| Solar Energy: Zon Engineering Inc. | |

| Geothermal: Geo-Xergy Systems | |

| Noise Engineer: Novus Environmental (now part of SLR) | |

| Construction Management: Maple Reinders Constructors Ltd | |

| Photography Credits: | Philip Castleton |

©Philip Castleton

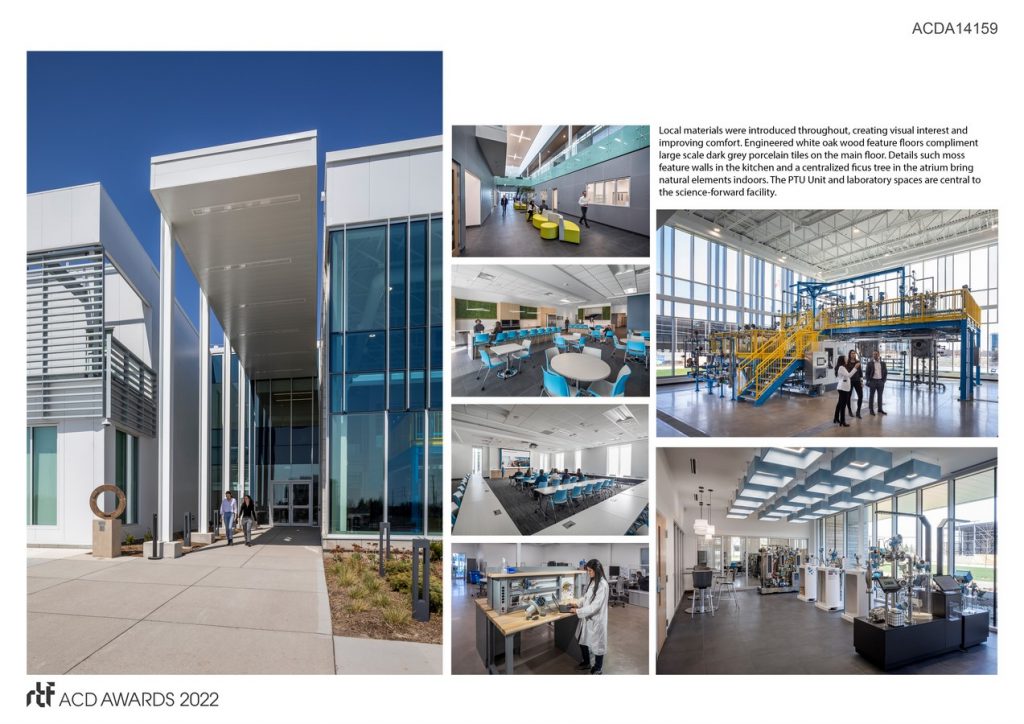

Endress+Hauser, family owned and run, sees each new building as a gift for its employees. The Customer Experience Centre is home to a wide variety of spatial typologies including workplace and administrative zones, the process training unit (PTU), multipurpose training rooms, workshops/repair areas, calibration process rooms, kitchen and cafeteria areas, fitness room, and warehouse space. It all supports sales, training, and repairs of its measurement instrumentation, services, and solutions for industrial process engineering. Our design prioritized natural daylighting, indoor air quality and creating opportunities for movement within and around the building.

The glass enclosed process training unit (PTU) is prominently positioned at the southeast corner, acting as the building’s public face, immediately an educational opportunity for visitors and connected visually to two of its boardroom areas, including one which cantilevers out into the PTU space for a bird’s eye view of the PTU in action.

©Philip Castleton

The atrium and corridor area visually connects with the calibration and specialized laboratory zones on one side and training, entertainment, and cafeteria zones on the other. It gave the Endress+Hauser team much more flexibility to host guests, employees and customers at events of various size and scale.

For the workplace areas, we spent time with its employees to gain a thorough understanding of the company’s culture and workflow. As a result, the open concept second floor houses employee working areas grouped into neighbourhoods, with slight shifts in layout to accommodate differing work types. A combination of open flexible work areas, breakout rooms and enclosed offices are organized around a central walking track within the triple height atrium, creating openness. To counter this openness, we paid special attention to the acoustics, facilitating employee comfort and focused work.

©Philip Castleton

An important design objective was to provide access to the outdoors. A large exterior patio extends along the southern façade of the second storey, with direct connections to the employee kitchen. Additionally, over 40% of the formerly vacant property has been dedicated to open space and landscaping. These areas have been planted with native, non-invasive and drought tolerant plant species that absorb and hold rainfall to reduce the amount of surface water runoff. A walking trail encircles the sites, a place for respite for its staff or the location of walking meetings.

The client team was well-versed in advanced technologies and excited to see how far we could push sustainability outcomes. Data informed our team’s decisions. The outcome is a high-performance building enclosure, creative mechanical system solutions, sustainable materials selection, supported by sustainable construction practices. The data tells us we can anticipate the site will produce more energy than the facility will require on an annual basis.

- ©Philip Castleton

- ©Philip Castleton

- ©Philip Castleton