“Cities account for 70% of the world’s energy consumption. Almost 50% of the energy is used for heating or cooling. District energy systems are one of the most effective ways to mitigate climate change…” District Energy in Cities: Unlocking the Potential of Energy Efficiency and Renewable Energy, United Nations Environmental Programme report (2015)

Architecture, Construction & Design Awards 2022

Second Award | Institutional (Built)

| Project Details | |

| Project Name: | District Energy Facility, Harvard University |

| Project Category: | Institutional (Built) |

| Studio Name: | Leers Weinzapfel Associates Architects, Inc. |

| Area: | 55,864 gsf |

| Year: | 2021 |

| Location: | Boston, MA |

| Photography Credits: | Brad Feinknopf |

| General Contractor: | Bond Brothers |

| MEP Engineer: | RMF Engineering |

| Structural: | Thorton Tomasetti |

| Landscape: | Reed Hilderbrand LLC |

| Lighting Designer: | Francis Krahe & Associates, Inc. |

| Acoustics Consultant / Engineer: | Accentech solutions co. Ltd |

| Civil: | VHB |

| Geotechnical: | Haley & Aldrich Bryan Sweeney |

| Air Permitting: | Epsilon Associates, Inc. Dorothy Buckoski |

©Brad Feinknopf

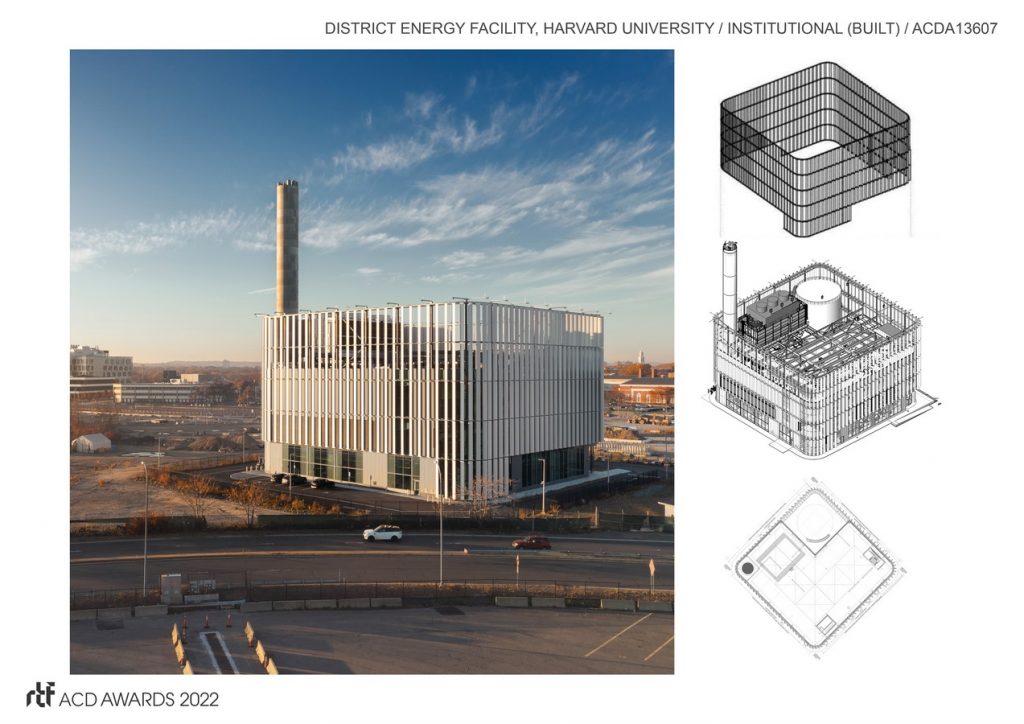

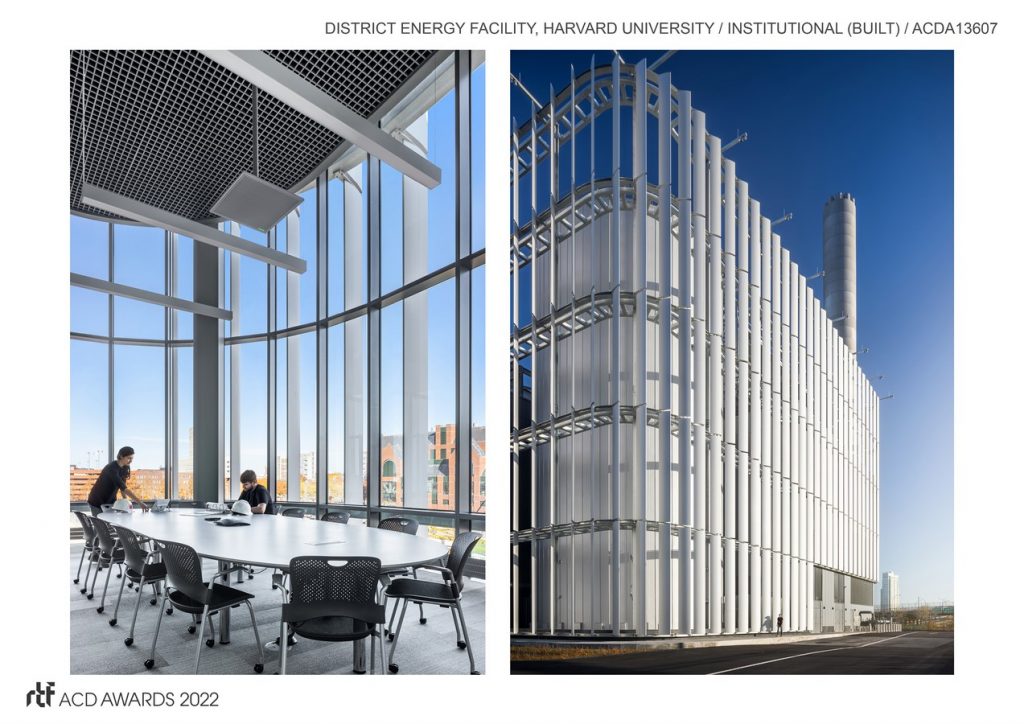

The new 56,000 sf District Energy Facility (DEF) sets the stage for a state-of-the-art, cost effective, and sustainable utility generation and distribution system for Harvard’s Allston campus that also makes a significant contribution to the urban design of the campus.

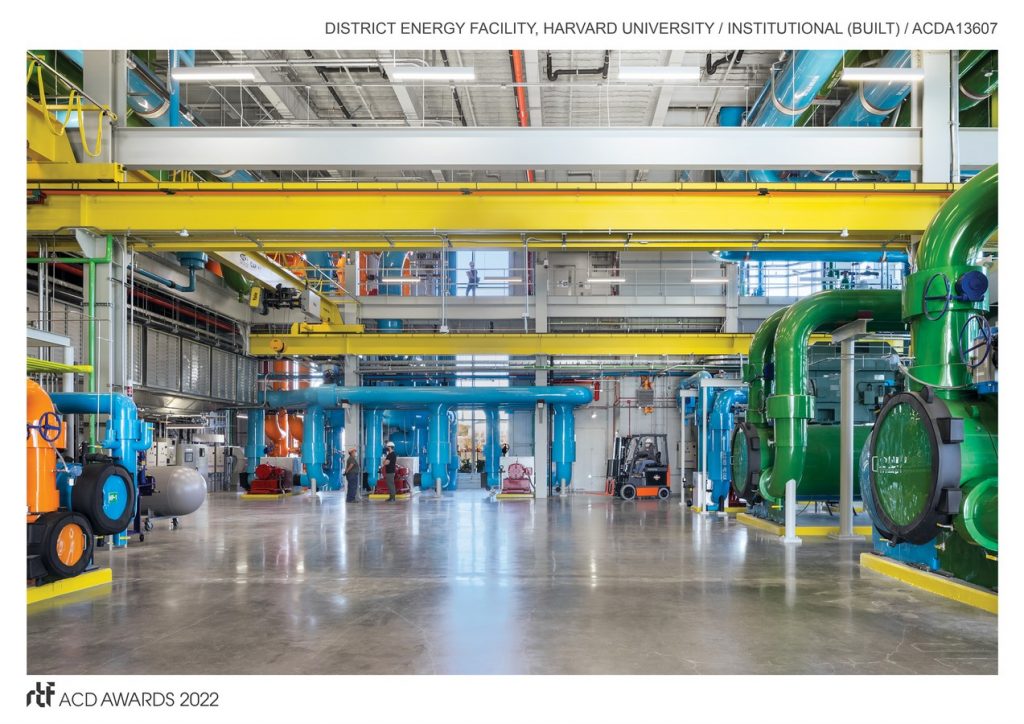

The building’s compact cubic form with rounded corners allows for maximum flexibility of future development around it while maintaining a singular bold and refined presence. A wrapper of anodized aluminum metal fins forms a screen around the facility, with petal-like elements set at varying degrees of openness to reveal or conceal the various equipment areas within. The exterior fins are most open at the structure’s corner entry, and most closed on its service sides. On the public faces of the building, the fins are raised to engage the community through technology on display. On the service side of the building, the fins are raised to allow vehicular access into the building and equipment access through large glass bi-fold doors. The inner façade is composed of insulated metal panels, curtain wall, and louvres; each side uniquely addresses specific equipment requirements and interior layout. Materials were chosen for durability, ease of maintenance, acoustics, and sustainability. A high design priority was workplace safety, security, accessibility, and wellness; abundant natural light is an additional feature of all workspaces.

©Brad Feinknopf

Formerly relegated to the “backyard” of a campus with little visibility, today’s infrastructure plants are more centrally located to serve multiple buildings in a district and therefore face the pressures of relating in scale to nearby structures as well as mitigating noise and air quality. An innovative approach is required to celebrate their energy and robust beauty and to make them good neighbors.

The DEF is one of the first new buildings to be completed on the Allston campus, therefore carrying the responsibility of setting a high standard of quality and design as well as of creating a visible demonstration of sustainable practice in building, landscape, and storm water management. Occupying a previously deserted railyard, the project introduces native vegetation and water management to activate the area’s biodiversity and minimize stormwater runoff. Resiliency, flexibility, and innovation are key goals for the design to transition to a fossil-fuel-free future, withstand climate impacts including storm surge flooding, and provide a reliable, resilient source of heating, cooling, and electricity to the Allston campus. The DEF building and site is certified LEED Gold.

©Brad Feinknopf

The site for the District Energy Facility is at a pivotal location in the new development area with a highly visible presence from all sides. It is a permanent support facility and therefore its building and site design complements the future campus evolution, including open space, academic buildings, and research and development spaces.

- ©Brad Feinknopf

- ©Brad Feinknopf

- ©Brad Feinknopf