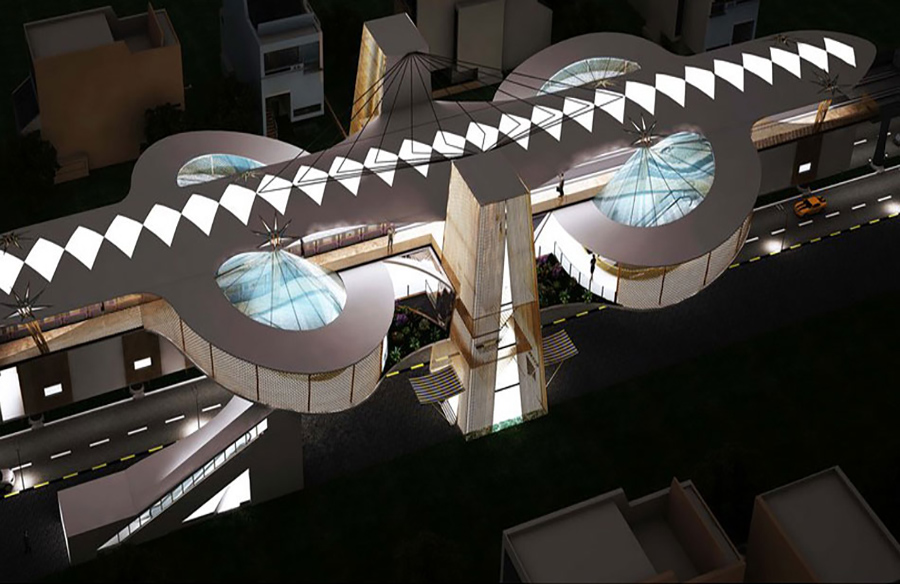

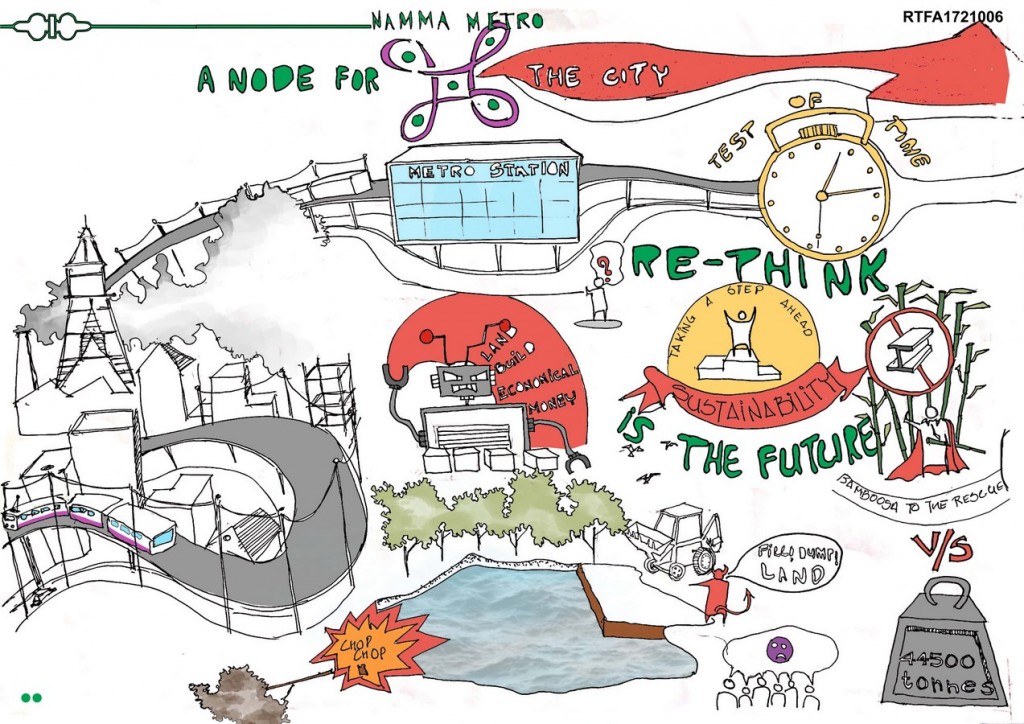

Context: The cities of today are experiencing a burst of infrastructure and building construction activity to cater to the ever-increasing population. In order to reduce the carbon footprint of infrastructure projects, it is important that we account for the energy that is embodied in the material that we usein their construction. Our quest has been to explore the various ways of using materials and construction systems with low embodied energy and carbon emissions and make sincere efforts to reduce these in infrastructure projects.

Second Award | RTFA 2017 Awards

Category: Transportation Terminal (Concept)

| Project Details | |

| Studio Name: | Manasaram Architects |

| Team Members: | Manasaram Architects Marel Drego |

| Country: | India |

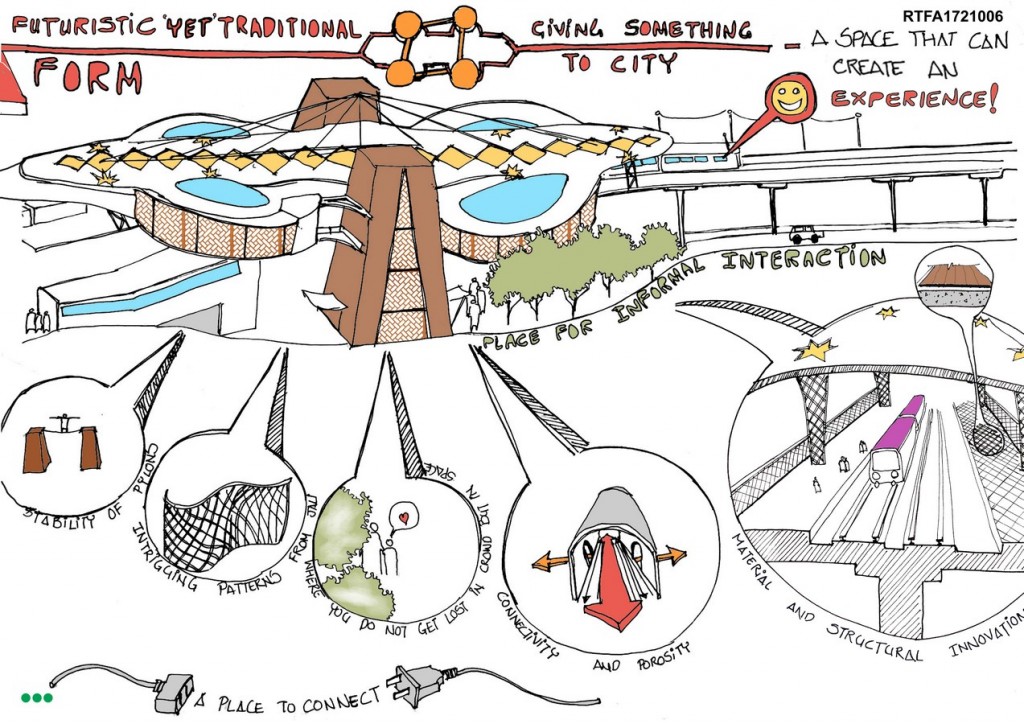

| The Design Concept: Form – | Connect to people emotionally |

| Material – | low energy local materials sustainably in a contemporary vocabulary. |

| Services – | self regulating |

©Manasaram Architects

Challenges and Innovations: Bamboo is introduced in the design to showcase its potential how a traditional fragile looking material can be used to an in large infrastructure projects. Bamboo was introduced in response to huge amount of steel used in large infrastructure projects which lead to immense carbon emission eventually leading to global warming. In the project, Bamboo is taken to new level in the design by incorporating it in various forms. ”Bamboo is the new steel”

©Manasaram Architects

Advantages compared to competitors: This innovation has several advantages compared to its competitors. To name a few.

- Bamboo being unquestionably sustainable with low energy balance, this system is extremely light in its carbon footprint. On an average a building with Bamboo with a usage of nearly 50-60%, the building would be nearly 7 (seven) times more sustainable compared to a similar construction with steel and concrete etc.

- This structural system is very low in cost/sq.ft. as well and hence it is extremely economical for large buildings. The cost could be brought down by over close to 20-25%

- The materials required for this system is available locally. And it does not require highly skilled, work force. Hence it can be executed with utmost ease almost anywhere with minimal guidance.

- All the ancillary structures are proposed with blocks made from waste from the construction of underground metro stations.

- ©Manasaram Architects

- ©Manasaram Architects