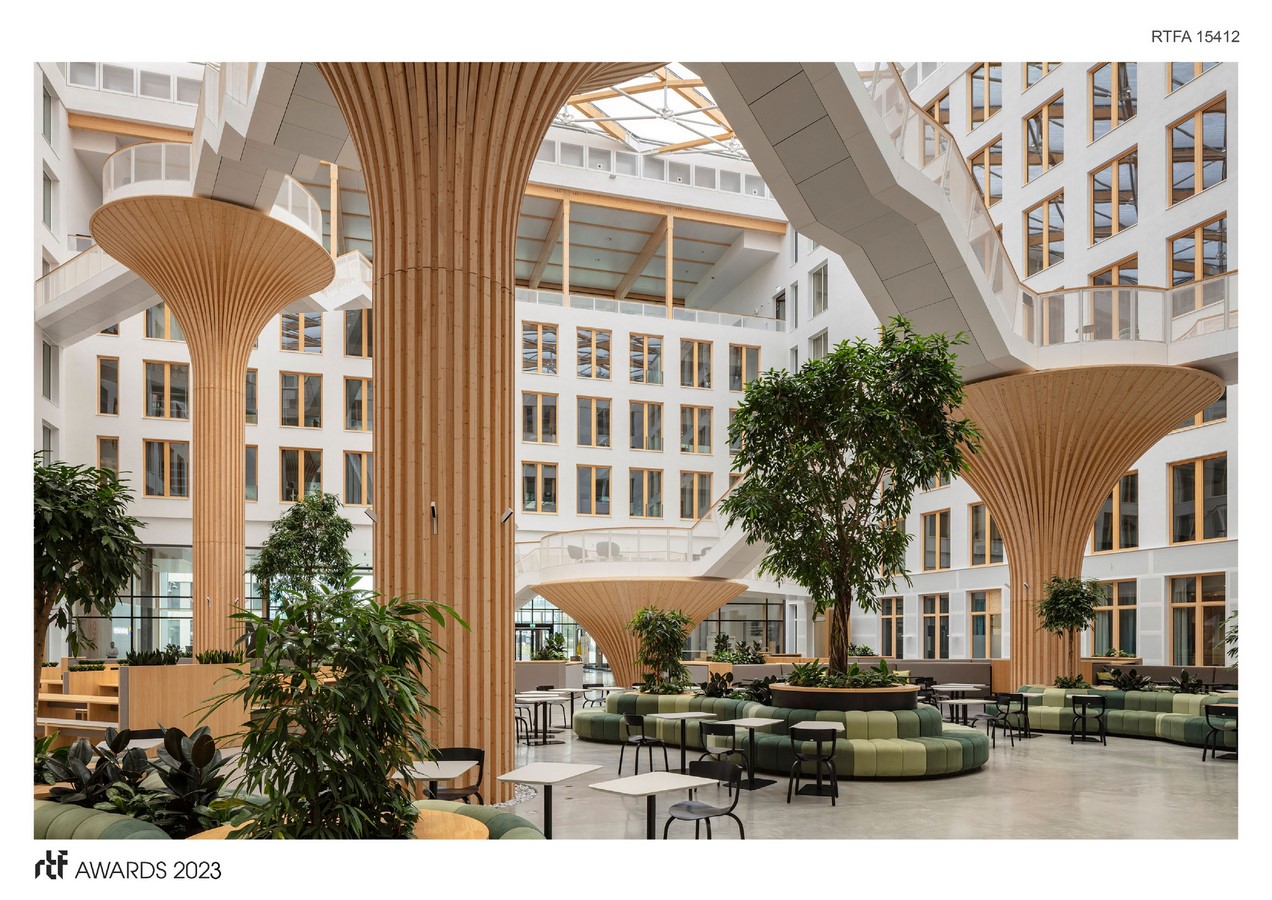

The seven-storey office ensemble EDGE Suedkreuz Berlin was built sustainably using a modular timber hybrid construction method. The larger of the two freestanding buildings covers around 20,000 m² of floor space, making it the largest wood-hybrid building in Germany in terms of area in the long term. The German Sustainable Building Council (DGNB) named the project Germany’s most sustainable building in 2022.

Rethinking The Future Awards 2023

First Award | Sustainable Project of the Year (Built)

| Project Details | |

| Project Name: | EDGE Suedkreuz Berlin |

| Category: | Sustainable building of the year |

| Studio Name: | TCHOBAN VOSS Architekten GmbH |

| Design Team: | Architect: Sergei Tchoban |

| Project partners: Stephan Lohre, Karsten Waldschmidt | |

| Team: | Julia Angelstorf, Lev Chestakov, Giorgia Fontana, Ulrike Graefenhain, René Hoch, Anastasia Kapustina, Valeria Kashirina, Birgit Koeder, Achim Linde, Fabiana Pedretti, Dennis Petricic, Manuela Peth, Soeren van Ost, Fabio Prada, Anja Schroth, Katharina Stranz, Carolin Trahorsch |

| Collaborating architects: | Service stage 5: granz + zecher architekten GmbH, Berlin |

| Area: | 32,000 sqm |

| Year: | 2022 |

| Location: | Berlin, Germany |

| Consultants: | General contractor: ARGE SXB, Suedkreuz Berlin ZECH Bau GmbH, CREE Deutschland GmbH, Rhomberg Systemholzbau GmbH represented by ZECH Bau GmbH, Berlin |

| Project management: SMV Bauprojektsteuerung Ingenieurgesellschaft mbH, Berlin | |

| Landscaping: service stages 1-4, hochC Landschaftsarchitektur, Berlin; service stage 5, granz + zecher architekten GmbH, Berlin | |

| Structural engineering: Buro Happold GmbH, Berlin; BIT Buero fuer integrale Tragwerksplanung GmbH, Berlin | |

| Building technology: Buro Happold GmbH, Berlin | |

| Sustainability consulting and DGNB/WELL certification: Buro Happold GmbH, Berlin | |

| Interior design: de Winder Architekten GmbH, Berlin | |

| Façade planning: Arup Deutschland GmbH, Berlin | |

| Photography Credits: | HG Esch |

| Render Credits: | TCHOBAN VOSS Architekten |

©HG Esch

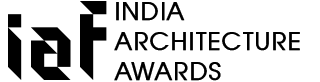

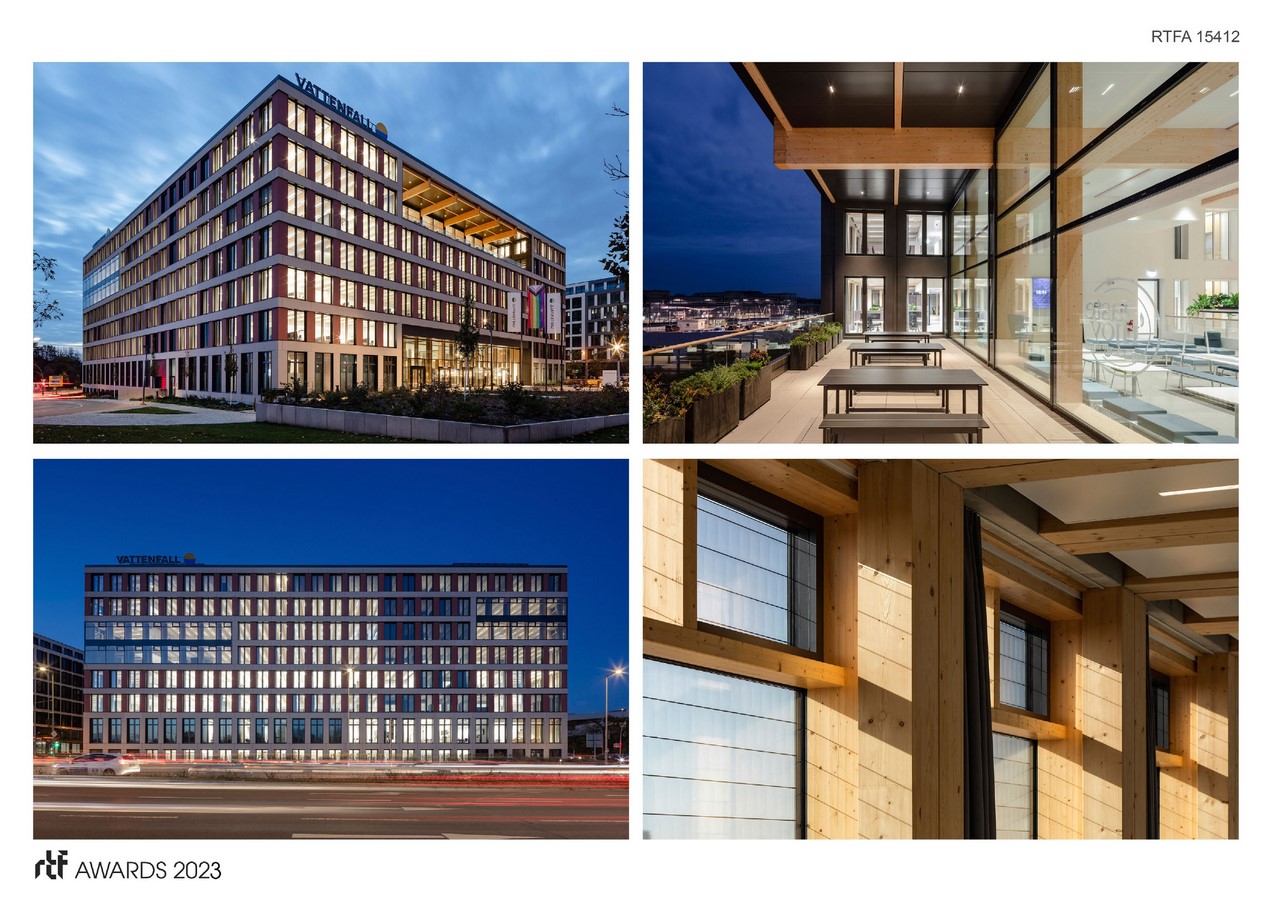

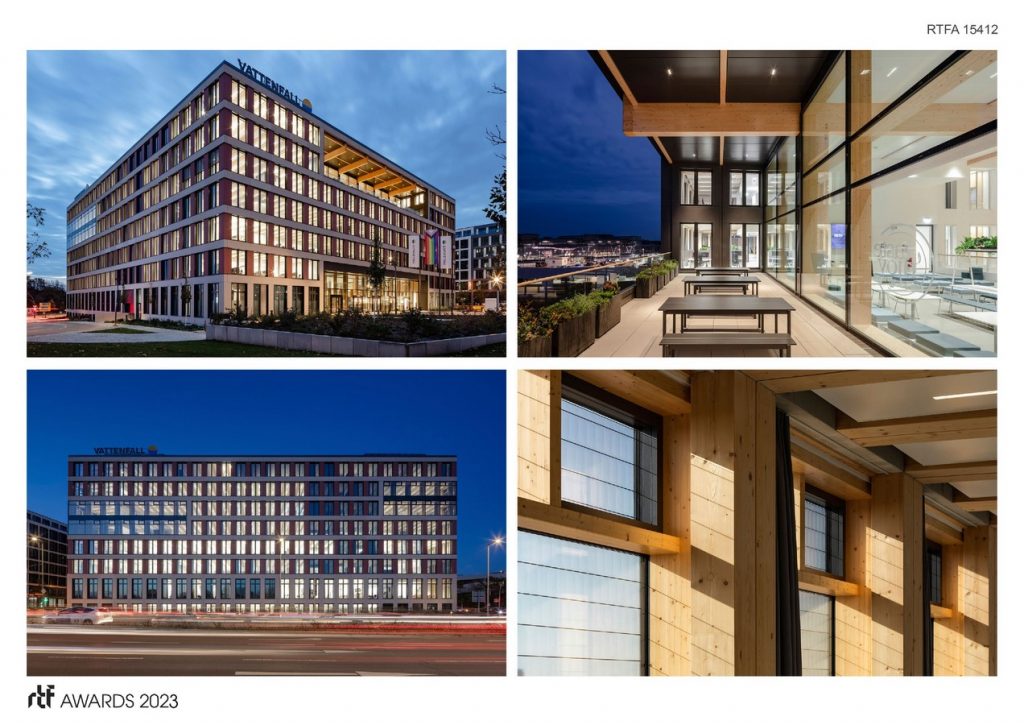

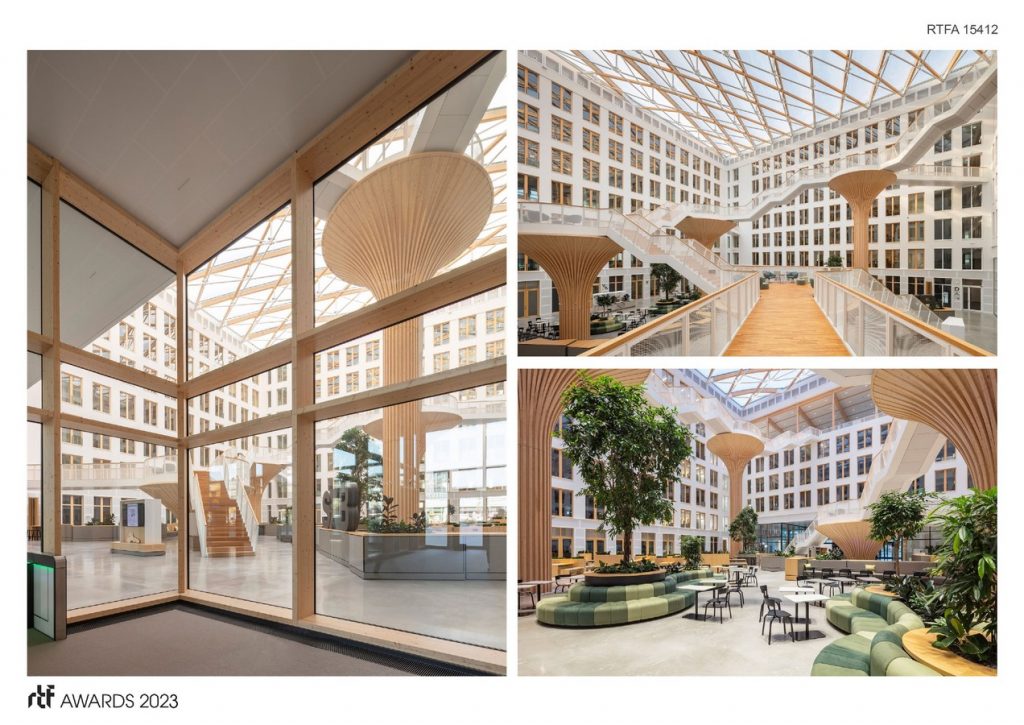

The heart of the Carré is formed by a light-flooded atrium, spanned by a transparent ETFE foil roof that rests on a wooden truss construction. The central eye-catchers are the four tree-like structures, graduated in height, whose platforms are connected to each other and to the office floors by filigree staircases and bridges. On the fifth floor, the sky lounge with panoramic façade and outdoor terrace opens up to the atrium. The offices are air-conditioned by suspended Smart Ceilings (heated-cool ceilings). All office areas as well as the associated ancillary and circulation areas can be used barrier-free.

In the construction of the buildings, the focus was on reducing the carbon footprint as much as possible, especially the weight of the complex, and on using sustainable materials that can be recycled according to the cradle-to-cradle principle. EDGE Suedkreuz Berlin is the first project nationwide to be recorded on the MADASTER material database for the building structure with a 100% match. It has a material passport that enables the materials used to be reused and recycled.

The use of prefabricated modules had a positive impact on various aspects of the construction process. The timber construction elements such as wall and ceiling modules were prefabricated in the factory, directly assembled and fine-tuned at the construction site. This ensured exact construction scheduling and a particularly time-efficient and thus economical construction process.

©HG Esch

The natural material wood is found everywhere in interior and office spaces and makes an important contribution to a permanently healthy indoor climate for the users. In addition, the material is lighter and more energy-efficient to transport than mineral building materials. Around 3,500 m³ of PEFC-certified spruce wood was used in the building construction.

Due to an approx. 50% saving of reinforced concrete compared to conventional in-situ concrete construction, the construction-related CO2 footprint of the ensemble is correspondingly lower. Industrial pre-production (also of the lightweight façades) and the use of wood were essential building blocks. A low construction weight, shorter shell construction times, high planning and cost security and long durability are further advantages of this construction. With an extensive deconstruction concept, the issue of circularity was integrated into the planning at a very early stage.

©HG Esch

The façades are constructed in an even grid of weather-resistant glass-fibre concrete panels that weigh only 30 kg/m². They are approximately 80% recyclable and have a decarbonising effect due to their special surface structure.

EDGE Suedkreuz Berlin received the DGNB Platinum certificate with the highest rating ever achieved in Germany of 95.4%. In addition, the ensemble was certified with DGNB Diamond for its outstanding design and architectural quality. WELL v2 Platinum certification is being sought.